what is waste incineration fly ash

Waste incineration fly ash refers to the small particulate matter collected and settled by the flue gas purification system during the waste incineration process, mainly including two substance: botton ash and fly ash. Fly ash usually contains relatively high levels of heavy metals, dioxins and other toxic and harmful substances. Therefore, proper treatment is required to prevent harm to the enviroment and human health.

process principle

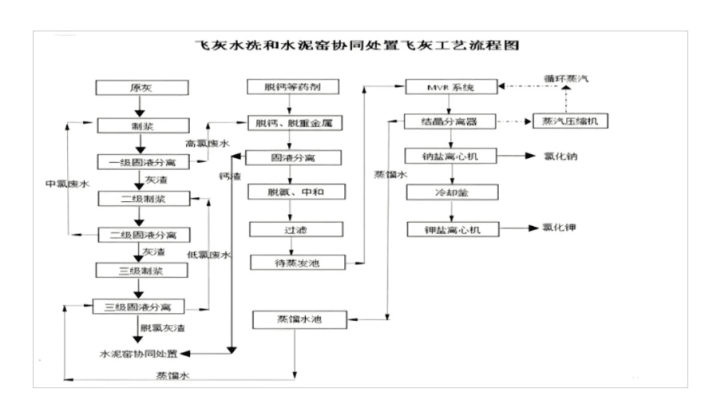

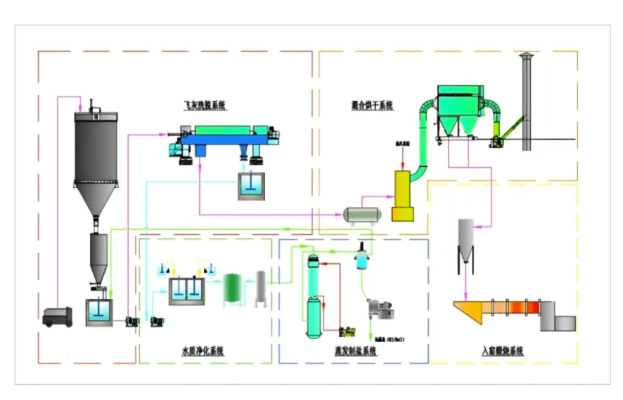

The “fly ash water washing+cement kiln co – disposal process” uses fly ash elution technology, water – washed ash drying technology, ash – washing water purification technology, purified water salt – making technology, and dried ash cement kiln co – calcination technology to treat fly ash. This technology realizes the harmless disposal to fly ash and obtains considerable cement raw materials and by – produces the scare potassium salt resources in our country.

Process Flow Diagram

The “fly ash water washing + cement kiln co — disposal process” consists of five major system: the fly ash elution system, the water quality purification system, the evaporation and salt – making system: the drying system, and the kiln – feeding and calcination system. The first four systems are for fly ash water washing and dechlorination, and the fifth system is for cement kiln co – disposal.

Problem Analysis of traditional sodium - potassium evaporation and salt - separation technology

The salt crystals precipitated by the traditional sodium – potassium salt – separation process are relatively small and difficult to separate, and both the recovery rate and purity of potassium chloride are relatively low.

Most traditional processes for extractiong potassium salt either use a cooling kettle or a flash evaporation tank for flash evaporaiton and cooling to extract potassium. When using a cooling kettle to extract potassium, it is an intermittent operation. Due to the constant fluctuation of the “stabilizer”, the purity of potassium salt fluctuates greatly, the degree of automation is low, the operation is inconvenient, and continuous operation is impossible. Thus, this process is gradually being eliminated.

Currently, the fly ash industry mainly uses flash evaporation or cooling for potassium extration.

However, the traditional flash evaporation and cooling systems mainly have the following problems:

1.Excessively high temperature: During the flash evaporation operation, an excessively high temperature will cause the weakening of intermolecular interactions, making it difficult to form relatively large – sized potassium chloride particles in the flash evaporation tank, thus affecting the recovery rate of potassium chloride.

2.Excessively high concentration: When the solution concentration is too high, the intermolecular interactions of solute molecules are enhanced, and only relatively small particles can be formed.

3.Excessively fast crystallzation speed: During the flash evaporation process, the crystal growth time is relatively short, resulting in relatively small crystal particles.

Description of sodium - potassium salt separation process

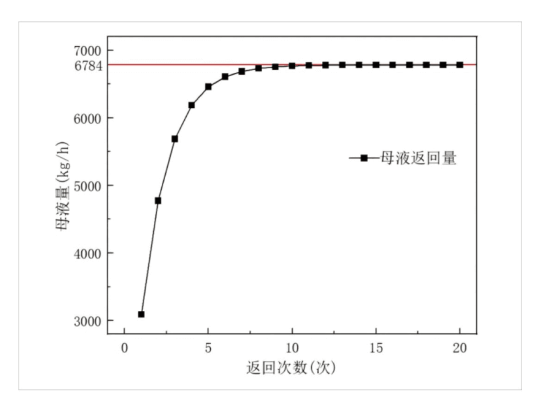

Use aspen plus to establish a model, and then use calculation software to perform simulation calcutions to find the “convergence point”(stabilizer). Through repeated simulation calculations, the relationship between the salt recovery rate purity under different “convergence point” can be analyzed, which can be used as a basis for guiding production during the actual operation process.