Anti-scaling innovation solution for FGD effluent evaporation

Introduction

High-salinity wastewater generally refers to wastewater with a salinity significantly higher than that of conventional surface water or ordinary water for production and domestic use. In 2015, the Ministry of ecology and Environment of People’s Republic of China issued the “Enviromental Access Conditions for Modern Coal Chemical Construction Project (Trial),” which sitpulates that in areas lacking sewage – receiving water bodies, effective disposal measures should be taken for high – salinty wastewater, and groundwater, atmosphere, soil, etc. must not be polluted. This situation is particularly prominent in China’s coal chemical industry. In the early days, the mixed miscellaneous salt was produced during the evaporation and crystallization stage of high-salinity wastewater in China, and it was disposed of as hazardous wastewater at a high cost. Therefore, the resource utilization of crystalline salt in the zero-discharge treatment process of high-salinity wastewater is imperative.

Process Introduction

The evaporation and salt separation process for high-salinity wastewater is the main process technology to achieve zero discharge of wastewater and resource utilization of crystallization salt. The mine water in different regions and the coking wastewater generated by different processes can turn waste into treasure through the salt separation process, reducing the enterprise’s wastewater disposal cost.

In industries such as mine water and the coal chemical industry, high-salinity wastewater mainly contains sodium sulfate and sodium chloride. Taking advantage of their different solubilities at different temperatures and coming with a phase diagram, different salt separation processes are adopted for separation.

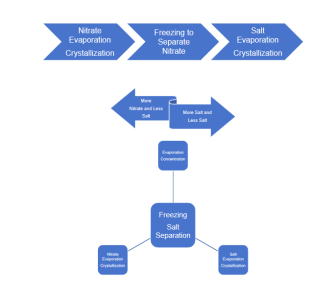

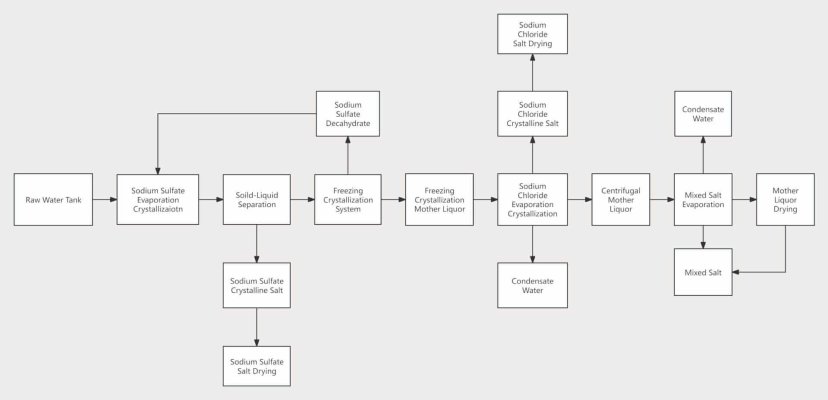

thermal crystallization + freezing crystallization

When the concentration difference between sodium chloride and sodium sulfate is not large, first, the evaporation and crystallization of sodium sulfate are carried out. The centrifugal mother liquor undergoes freezing crystallization, and the produced sodium sulfate decahydrate is returned to the sodium sulfate evaporation and crystallization system to produce sodium sulfate crystalline salt. The freezing mother liquor is sent to the sodium chloride evaporation and crystallization process to produce sodium chloride crystallization salt. The centrifugal mother liquor from the sodium chloride evaporation and crystallization is subjected to mixed salt evaporation to produce mixed salt.

concentration + freezing + recrystallization

For wastewater with relatively low concentration of sodium chloride and sodium sulfate and a relatively close salt – nitrate ratio, first evaporation and concentration are carried out. Then, sodium sulfate decahydrate is crystallized out by freezing. After recrystallization, sodium sulfate crystalline salt is obtained. The frozen mother liquor is evaporation and crystallized to obtain sodium chloride crystalline salt. The centrifugal mother liquor of sodium chloride is subjected to mixed – salt evaporation to produce mixed salt.

direct freezing + recrystallization

For wastewater with a relatively large salt-nitrate ratio and a relatively high organie matter content, sodium sulfate decahydrate can be directly crystallized by freezing. Then, sodium sulfate crystalline salt with relatively high purity is obtained through recrystallization. The frozen mother liquor is evaporated and crystallized to produce sodium chloride crystalline salt. The centrifugal mother liquor from the evaporation and crystallization of sodium chloride is subjected to mixed salt evaporation to produce mixed salt.