Anti-scaling innovation solution for FGD effluent evaporation

Vapor compression or vapor generation provides your process with an efficient heat recovery system.

- MVR (Mechanical Vapor Compression) operates on the core principle that steam produced during a process can be directly compressed for subsequent heating applications. For waste heat streams in the form of non-compressible liquid or steam, a heat pump cycle incorporating an evaporator (steam generator) offers a viable solution.

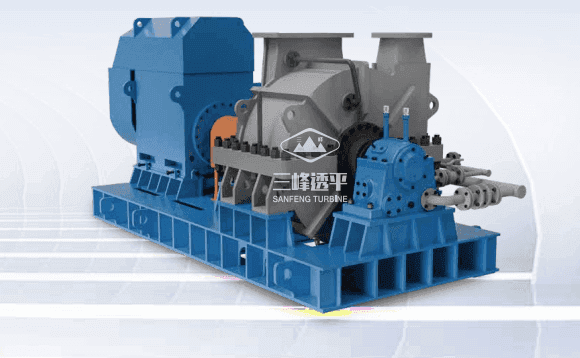

- Within conventional vapor compression systems, Sanfeng blowers and compressors elevate steam directly to the temperature and pressure specifications required for heating purposes. The compressed steam my then serve as a direct heat source across various processes or be utilized for steam or hot water generation.

1. In scenarios where no gaseous waste heat source is available, or where steam compression is either unfeasible or inadvisable, a heat pump cycle with an integrated evaporator becomes the optimal selection. The key distinction is such heat pump systems first generate steam within the evaporator, with water typically employed as the medium for producing low-pressure, low-temperature steam in this component.

2. The critical elements of this system are Sanfeng products. These units execute a sequence of compression stages on the steam to achieve the requisite pressure level, resulting in the production of steam at a usable boiling temperature. The recovered heating steam can be integrated into the steam network to supply heat for the original process or other industrial processes.