QUESTIONNAIRE EVAPORATION TECHNOLOGY

To partners in the chemical, steel, power generation, and desalination industries:

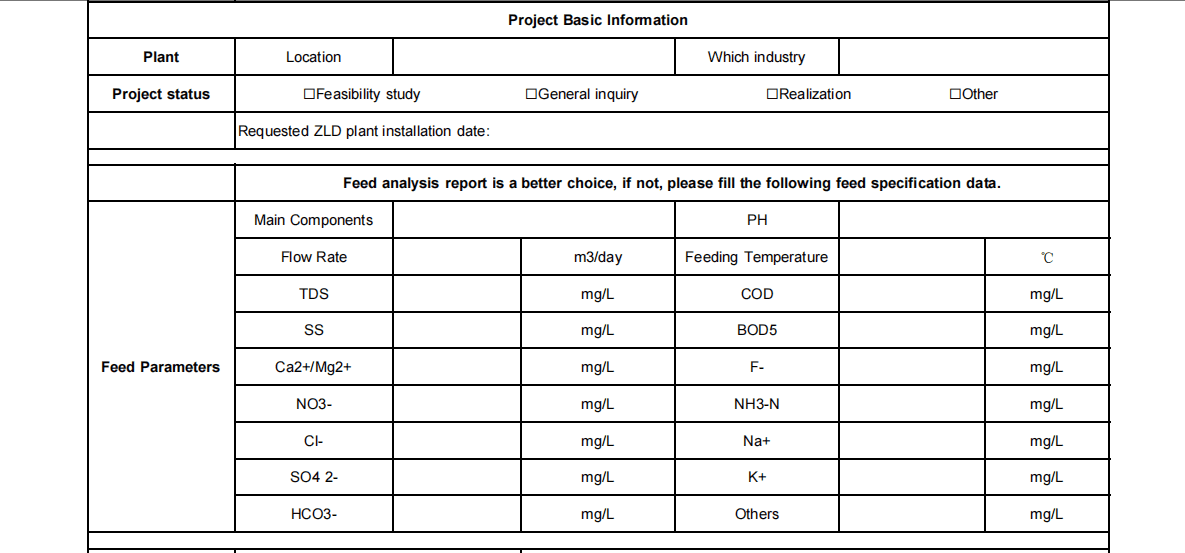

When you are confronted with the problem of feed analysis in an evaporation crystallization project, this feed analysis will be the key to breaking the deadlock. It is not merely a set of test data, but also the “gene map” of our customized full-process solution for you – just provide the test results of the content of various substances in the raw liquid, and we can precisely match the process parameters, achieving dual optimization of crystallization efficiency and cost control.

I. Chemical Industry: Precise Mapping from Components to Processes

The common strong acid/strong base systems and high-concentration organic solutions in your production will be presented in the feed analysis as indicators such as pH value, COD/BOD, and heavy metal ions (such as Cu²⁺, Ni²⁺). For example: When the Cl⁻ concentration in the wastewater is detected to be greater than 500ppm, we will configure a titanium evaporator for you to resist corrosion. If the sulfate content exceeds the standard, the risk of scaling in the crystallization reactor can be reduced from the source through the calcium and magnesium ion precipitation process in the pretreatment stage, and the purity of your chemical crystallization products can be increased to over 99%.

Ii. Steel/Power Generation Industry: The Protective Code for Circulating Water Systems

The concentrations of Ca²⁺ and Mg²⁺ in the circulating cooling water that you are concerned about, as well as the content of suspended solids (SS), are precisely the core indicators of the water quality meter. Take a certain steel enterprise as an example: When the feed analysis shows that the turbidity is greater than 20NTU, we control the SS below 5NTU through a combined process of pre-multi-media filter and ultrafiltration membrane. Combined with the regulation of evaporation temperature gradient, the concentration ratio is increased from 3 times to 8 times, saving more than 1 million yuan in water replenishment costs annually. This means that each set of your feed analysis data can be transformed into specific solutions for extending the equipment’s lifespan and reducing energy consumption per ton of water.

Iii. Seawater Desalination Industry: A Scientific Yardstick for Salt Separation

The concentration distribution of ions such as Na⁺, K⁺, Ca²⁺ , and Mg²⁺ in seawater/brackish water forms a unique “ion fingerprint” in the feed analysis. For the seawater desalination scenario, we customize multi-stage flash evaporation or reverse osmosis + crystallization combined process based on feed analysis data. When Mg²⁺ > 1200ppm is detected, we prevent scaling in the evaporation section through a pre-alkali precipitation process. At the same time, we utilize heat pump technology to recover condensation heat, keeping the energy consumption per ton of water below 8kWh. It saves more than 30% of energy compared with traditional processes.