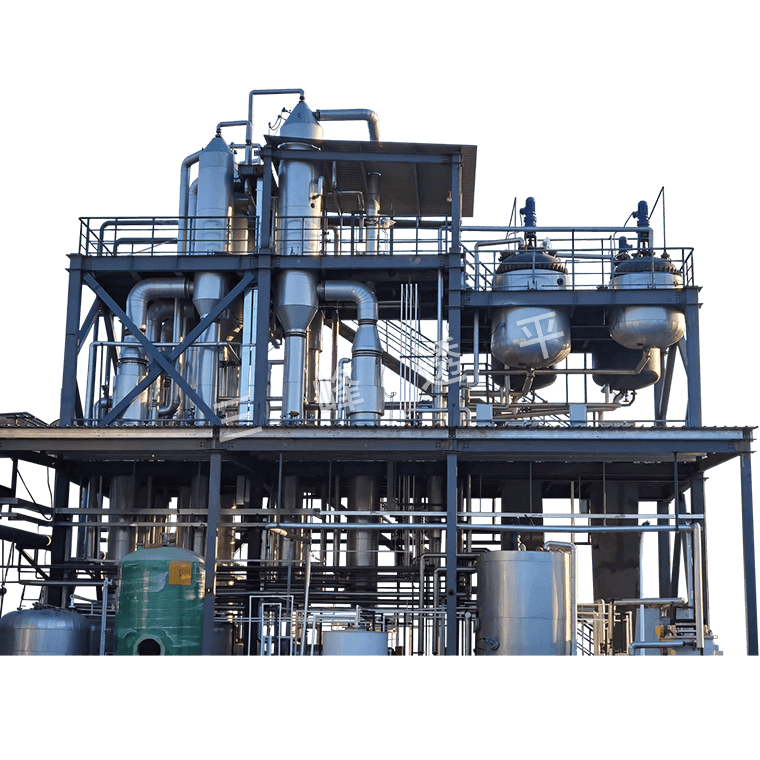

Steam Compressor Applicated in Heat Recovery and Heat Pump System

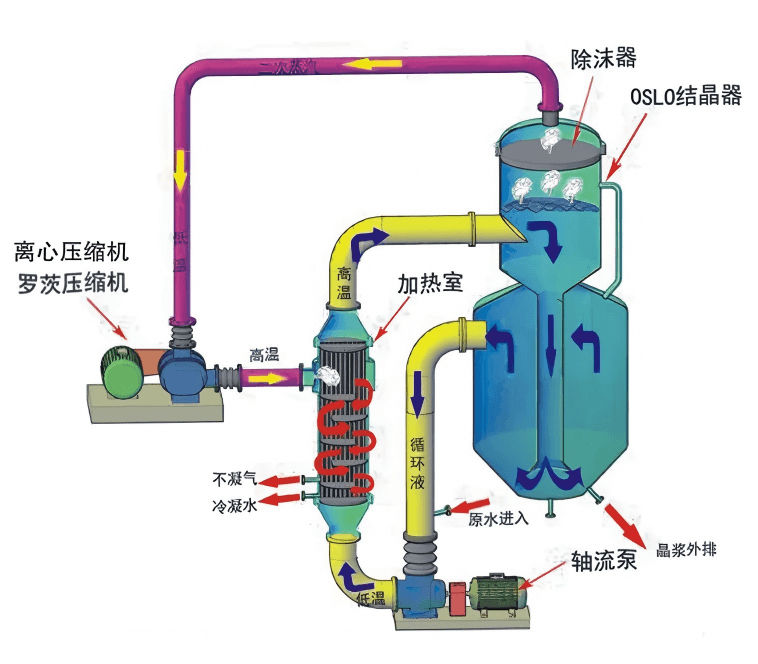

Anti-scaling innovation solution for FGD effluent evaporation Home Vapor compression or vapor generation provides your process with an efficient heat recovery system. MVR (Mechanical Vapor