Anti-scaling innovation solution for FGD effluent evaporation

Petrochemical Wasterwater

High-salinty wastewater refers to wastewater with a salt mass fractionn of not less than 1%. It not only contains soluble inorganic ions such as Cl−, SO42−, Na+, and Ca2+, but also contains refratory organic pollutants and total dissolved solid (TDS) with a mass fraction of not less than 3.5%. Due to the complex composition, high volatilty, and high toxicity of high-salinity wastewater, in order to meet strict enviromental protection requirements, industrial wastewater treatment technologies are constantly being updated and improved. At present, concentration technology, crystallization technology, and the coupling and synergy of the two technologies are widely used to achieve zero discharged of high-salinity wastewater resource utilization.

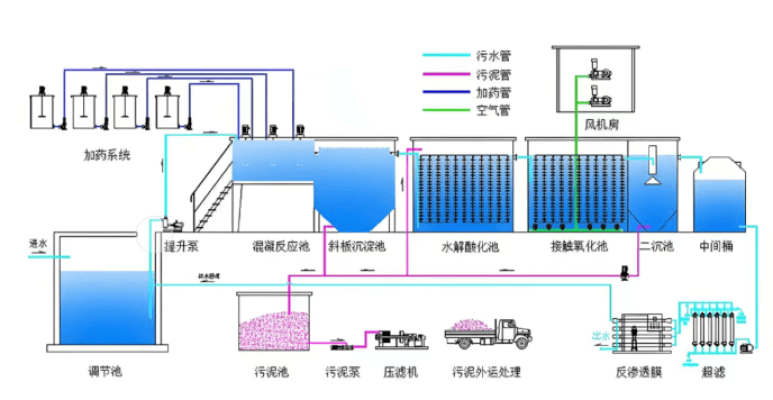

pretreatment

According to the actual situation of high-salinity wastewater, it is sometimes necessary to add pretreatment technologies such as chemical precipitation, multi-media filtration, ion exchange resin, and adsorption before the concentration technology to prepare for the subsequent concentration and crystallization processes.

(2)adsorption

The purpose of concentration is to reduce the volume of wastewater and improve the efficiency of subsequent evaporation and crystallization. Concentration technologies are divided into membrane concentration and thermal concentration according to different treatment objects and applicable scopes.

Membrance concentration technology takes pressure difference, concentration difference, and potential difference as driving forces, and realizes the separation, purification, and concentration of wastewater through the size difference between material components and the membrane, charge repulsion, and physicochemical effects. It mainly includes microfiltration(MF), ultrafiltration(UF), nanofiltration(NF) , reverse osmosis(RO), electrodialysis(ED), and membrane distillation(MD) ,etc.

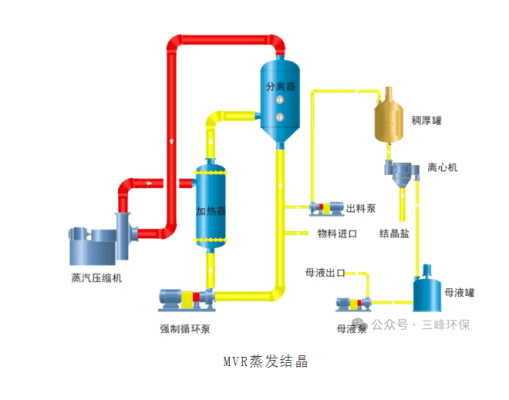

Thermal concentration technology is suitable for treating wastewater with high TDS and COD. It concentrates the ions in high-salinity wastewater at a high multiple by heating, and mainly includes multi-stage flash evaporation (MSF), multi-effect evaporation(MED), and mechanical vapor recompression evaporation(MVR).

(4)evaporation and desalination

For petrochemical wastewater with high COD or the concentrated membrane water produced after membrane separation, due to its relatively high salt content and the content of other impurities (such as COD, ammonia nitrogen, etc.), it cannot be directly discharged. Therefore, evaporators, as common desalination devices, are widely used in the petrochemical wastewater treatment industry. On one hand, the quality of the condensed water generated by evaporation is relatively good. It can either be reused as reclaimed water or directly discharged. The salt generated by evaporation is packaged and then transported outside for treatment.